AWI Performance Duty Level 3

Certified at AWI Performance Duty Level 3 - our millwork meets the highest standards of craftsmanship, durability, and design precision defined by the Architectural Woodwork Institute.

Machinery, Technology and Craftsmanship Built for Production-Grade Results

CNC machining • Automated workflows • Precision tooling

Tight tolerances, consistent quality, and scalable capacity

Trusted for commercial projects and high-demand residential work

Cutting • Edgebanding • Routing • Drilling • Assembly • Finishing Support

Our process ensures unmatched quality and precision from the very first stage of production. Every panel begins with rigorous material inspection and inbound cleaning, guaranteeing that only flawless components move forward. With robotic material handling and a fully automated feed-through work center, we deliver consistency, efficiency, and superior bonding strength across every panel.

Our composite panel manufacturing capabilities combine advanced automation with unmatched precision. Using state-of-the-art CNC machinery, we produce consistent, high-quality panels for architectural, commercial, and residential applications.

Our custom casework assembly operations are engineered for efficiency and flexibility - capable of handling both high-volume production and high-variation custom orders. Each build reflects our dedication to performance, fit, and finish.

The High-Pressure Laminate (HPL) Door Collection showcases superior design flexibility and resilience. Available in one-piece to five-piece laminate door styles, this line includes over 1,000 colors, textures, and finishes to match any design vision.

Our shipping and logistics operations are built around reliability, protection, and transparency. From packaging to delivery, every detail is designed to ensure your products arrive on time and in perfect condition. We combine protective packaging materials, clear labeling, and a trusted nationwide carrier network to maintain quality through every mile.

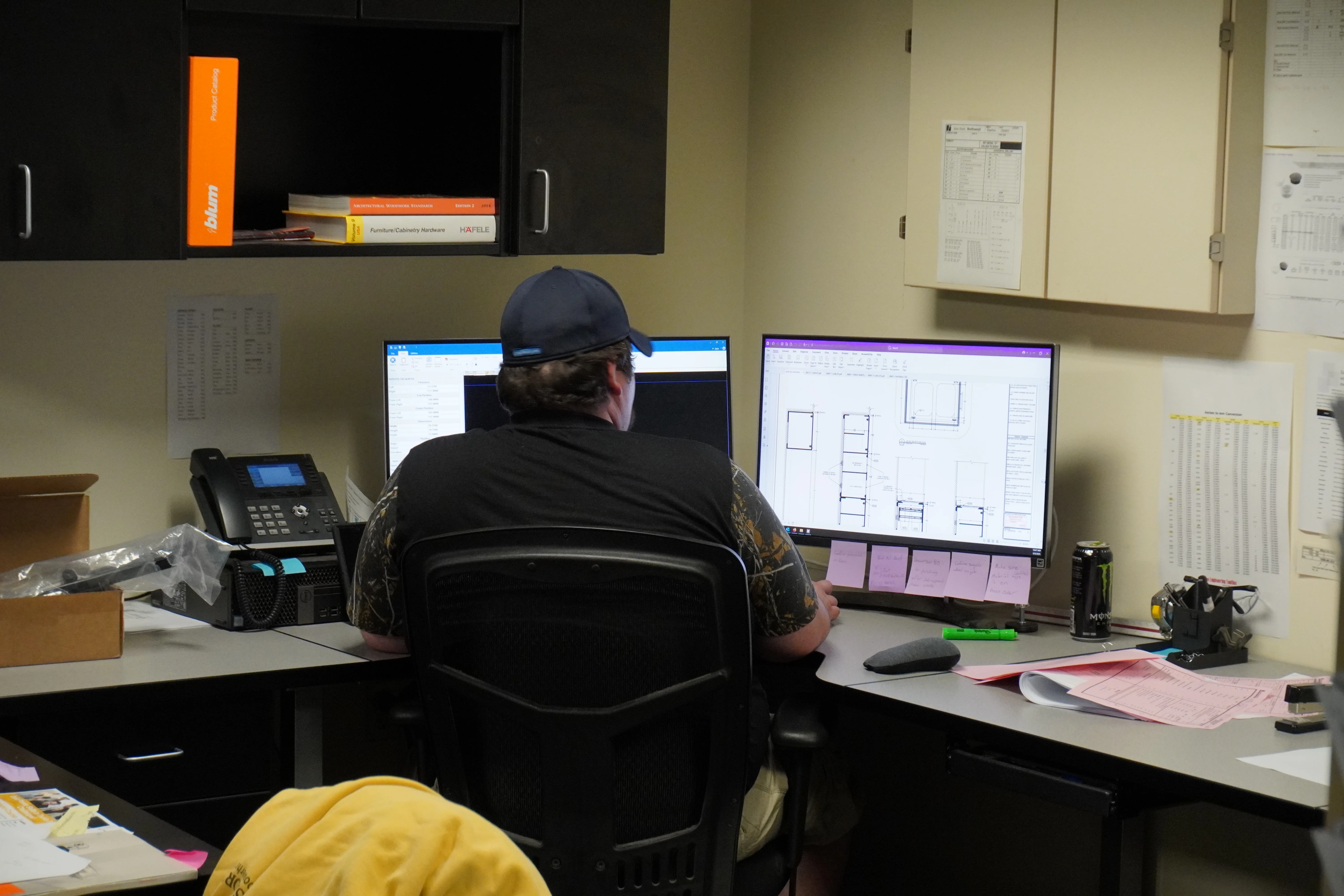

Share your project details with us and we'll provide a clear, timely estimate. To ensure accuracy, our estimating team performs quality checks on shop drawings, materials, and specifications before finalizing your quote. The more detail you provide-especially regarding materials and hardware-the better prepared we are to deliver precise pricing and timelines.

Need a sample before ordering? We're happy to provide components, cabinet door fronts, casework, and more to help you evaluate fit, finish, and material quality. Every request goes through an engineering quality check to confirm that drawings, hardware, and manufacturing methods align with your requirements. This ensures approved samples match final production outcomes.

Once your order is approved, it moves into production with rigorous in-process quality control at every stage-from panel processing and CNC machining to edgebanding and assembly. Our teams perform first-article inspections, checkpoint reviews, and final audits to maintain consistency and accuracy. Typical lead times are 4-6 weeks: ~2 weeks for engineering and procurement, followed by ~2 weeks for production. We also work with customers to expedite orders when possible.

We offer flexible shipping options, including blind shipping and private-label packaging. Before anything leaves our facility, shipments undergo a final quality verification to ensure that packaging, labeling, and documentation are accurate and secure. Orders can be shipped directly to you or drop-shipped to your customers through our trusted carrier network.

Certified at AWI Performance Duty Level 3 - our millwork meets the highest standards of craftsmanship, durability, and design precision defined by the Architectural Woodwork Institute.

We incorporate LEED principles across our projects - optimizing material use, energy efficiency, and indoor environmental quality to support sustainable building practices.

Our FSC© Chain of Custody Certification ensures responsible sourcing. Every wood product can be traced back to responsibly managed forests that protect biodiversity and communities.

About

At Northway, quality means more than just checklists. Steve Wagner, Vice President of Training and Development, and Doug Walter, Quality Coordinator team up to lead our quality-related initiatives. Whether it's creating trainings to expand our team members' manufacturing competencies or investigating ways to improve our production process from quoting through shipping, Steve and Doug make sure that we are reliably producing high-products for our customers.