Capabilities

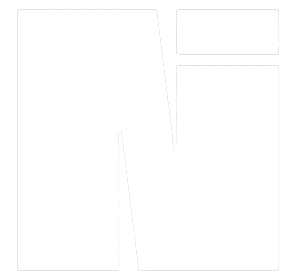

Laminate Components Manufacturing

Precision-cut laminate panels and components manufactured to keep fabrication moving-- accurate sizing, clean edges, and consistent output.

What We Manufacture

Laminate components and cut-to-size parts produced as building blocks for casework, fixtures, furniture, and architectural millwork.

Where These Components Get Used

Our laminate parts are designed to drop into real production workflows--supporting everything from one-off builds to repeat manufacturing.

Components may reference established commercial casework standards or client-specific specifications based on project requirements.

Casework & Cabinet Fabrication

- Box components cut square and ready for assembly

- Consistent sizing for repeat cabinet runs

- Reduced in-house panel processing

Fixtures & Retail Displays

- Shelves, dividers, and display panels

- High-finish exposed surfaces

- Repeatable parts for rollouts and refreshes

Architectural Millwork

- Wall panels, applied faces, and skins

- Consistent laminate matching across assemblies

- Support for custom and hybrid builds

Furniture & Worksurface Builds

- Desk panels, modesty panels, and partitions

- Clean edges ready for banding or assembly

- Batch production for repeat SKUs

Healthcare & Lab Environments

- Shelf and divider components for clinical spaces

- Durable, cleanable laminate surfaces

- Controlled revisions for ongoing renovations

Program & Multi-Site Manufacturing

- Standardized part libraries

- Revision-controlled components

- Predictable output for rollout schedules

Program Manufacturing & Repeat Parts

When components repeat, we help standardize details, manage revisions, and keep output consistent from run to run.

Standard Part Libraries

Establish repeatable part definitions with locked dimensions, edge specs, and materials.

Revision Control

Clear version tracking to ensure current parts are always what's in production.

Batch & Volume Runs

Production planned to support steady output without disrupting other work.

Labeling & Organization

Part identification that aligns with your shop flow or assembly process.

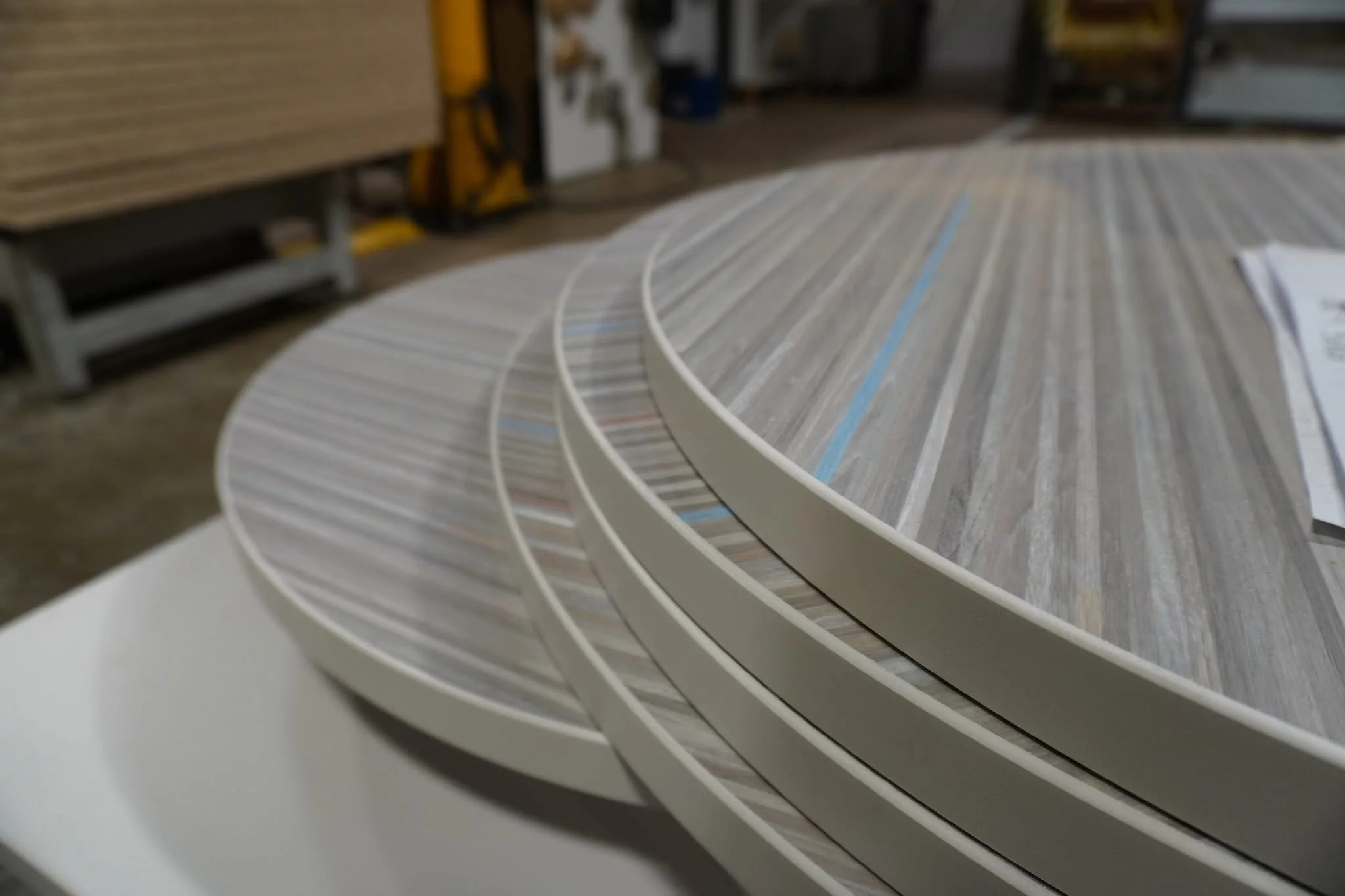

Materials & Processing Options

Flexible material and processing options to match performance, budget, and downstream workflows.

Materials

- Laminate: HPL and TFL

- Substrates: MDF, plywood, particleboard

- Thicknesses: matched to structural or cosmetic needs

- Finish matching: consistent color and grain direction

Processing

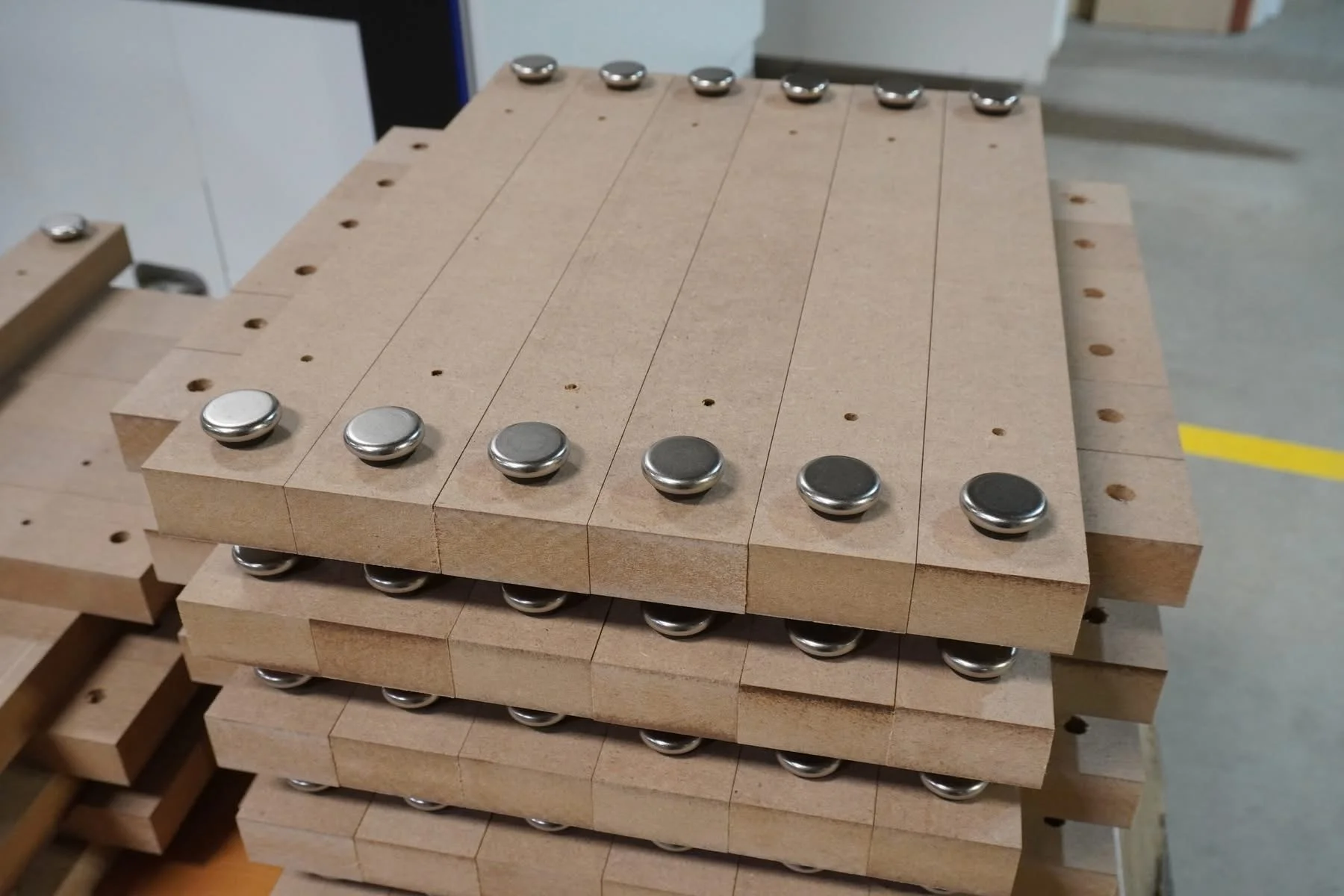

- Cut-to-size: square, accurate panels

- Edge prep: square for banding or specified edge finish

- Drilling: pattern-based or reference drilling

- Special handling: exposed-face protection

Component Quality Checkpoints

Quality checks focused on accuracy, consistency, and downstream usability.

Dimensional Accuracy

Panels verified for size, squareness, and repeatability.

Edge Condition

Clean cuts and edge quality suitable for finishing or assembly.

Finish Consistency

Color, grain direction, and laminate orientation checked across runs.

Labeling Verification

Part identification aligned with documentation and pack plans.

Need Laminate Parts or Panels?

Send part lists, drawings, or cut schedules. We'll quote based on scope and volume.

Start a Conversation or call us at 570-837-1574